Mastering the Build: How to Design a Bass-Reflex Speaker for Your Full-Range Driver

Introduction: The Pursuit of Sonic Purity with Full-Range Drivers

In the world of high-fidelity audio, there exists a dedicated group of enthusiasts who champion a seemingly simple component: the full-range driver. Their appeal is undeniable. By using a single driver to reproduce the entire audible frequency spectrum, they eliminate the need for complex crossover networks that can introduce phase shifts and other distortions. The result is a coherent, point-source soundstage often described as "magical," "holographic," or possessing an openness and directness that multi-way systems can struggle to replicate.

However, this sonic purity comes with a challenge. Physics dictates that a single cone struggles to reproduce the thunderous lows of a bass guitar and the delicate highs of a cymbal with equal authority. While many full-range drivers excel in the midrange, their low-frequency output can be limited. To unlock their full potential, especially in the bass department, a driver needs the right home: a carefully designed enclosure.

This is where the bass-reflex, or ported, enclosure comes in. It is a popular and highly effective method for extending a driver's bass response and improving its overall efficiency. By cleverly using the sound energy from the back of the cone, a bass-reflex design can help a modest full-range driver produce a surprisingly deep and powerful low end.

This article serves as a comprehensive, step-by-step guide for the DIY audio enthusiast. We will demystify the essential Thiele-Small (T/S) parameters and show you how to use them to design a custom bass-reflex enclosure tailored specifically to your full-range driver. By the end, you'll have the knowledge to move beyond guesswork and engineer a speaker that is a true marriage of science and sound, complete with a detailed, practical example to guide your build.

The Blueprint: Understanding Key Thiele-Small (T/S) Parameters

Before we can build a house, we need a blueprint. In speaker design, that blueprint is the driver's Thiele-Small (T/S) parameters. These are a set of electromechanical specifications that precisely describe a driver's behavior. Named after Australian engineers A. Neville Thiele and Richard H. Small, their work in the 1960s and 70s revolutionized loudspeaker design, transforming it from a trial-and-error art into a predictable science. As Audiophonics notes, these parameters are invaluable as they provide detailed information on the behavior and actual performance of a loudspeaker.

Understanding these parameters is not just academic; it is the fundamental requirement for designing any enclosure, especially a tuned system like a bass-reflex box. Without them, as Audio Judgement puts it, "you are blindfolded." Let's break down the most critical parameters for our task.

Core Parameters for Bass-Reflex Design

While a driver's spec sheet may list a dozen or more parameters, only a few are essential for the initial design of a bass-reflex enclosure.

- Fs (Free Air Resonance): Measured in Hertz (Hz), this is the natural frequency at which the driver's moving parts (cone, voice coil) resonate when suspended in free air, without an enclosure. It';s determined by the moving mass (Mms) and the suspension's compliance (Cms). A lower Fs generally indicates the driver has the potential to produce deeper bass frequencies. As a rule of thumb, a woofer with an Fs of 30 Hz will struggle to play frequencies significantly below that point.

- Qts (Total Q): This unitless parameter is arguably the most important for determining a driver's suitability for a particular enclosure type. It represents the driver's total damping at its resonant frequency (Fs), combining both its mechanical (Qms) and electrical (Qes) damping. The value of Qts acts as a powerful guide:

A general rule of thumb, supported by numerous sources like Audiophonics and DIY forums, is that a Qts lower than or equal to 0.4 is often ideal for a vented (bass-reflex) enclosure. A Qts between 0.4 and 0.7 is typically better suited for a sealed enclosure, and values above 0.7 may be best for open-baffle or free-air applications.

- Vas (Equivalent Compliance Volume): Expressed in liters or cubic feet, Vas represents a volume of air that has the same compliance (springiness) as the driver's own suspension (surround and spider). It's a measure of the suspension's stiffness. A driver with a "loose" suspension will have a high Vas, while one with a "stiff" suspension will have a low Vas. This parameter is a key variable in the formula for calculating the final enclosure volume (Vb). As BCAE1 explains, speakers with a loose suspension and high Vas tend to require larger enclosures.

Supporting Parameters

While the three parameters above are the primary inputs for our calculations, a few others provide important context and help in refining the design.

- Sd (Piston Area): The effective surface area of the driver's cone, usually measured in square centimeters (cm²). This tells you how much air the driver can move.

- Xmax (Maximum Linear Excursion): Measured in millimeters (mm), this indicates how far the cone can travel in one direction from its resting position while maintaining linear behavior. A higher Xmax generally means the driver can play louder at low frequencies with less distortion.

- Re (DC Resistance): The DC resistance of the voice coil, measured in Ohms (Ω). It will always be slightly lower than the driver's nominal impedance (e.g., an 8Ω speaker might have an Re of 6.5Ω).

- Qes (Electrical Q): A component of Qts, this measures the damping provided by the speaker';s "motor" system (the magnet and voice coil). It's a critical value used in a quick check to determine enclosure suitability.

The Science of Sound: Bass-Reflex Fundamentals

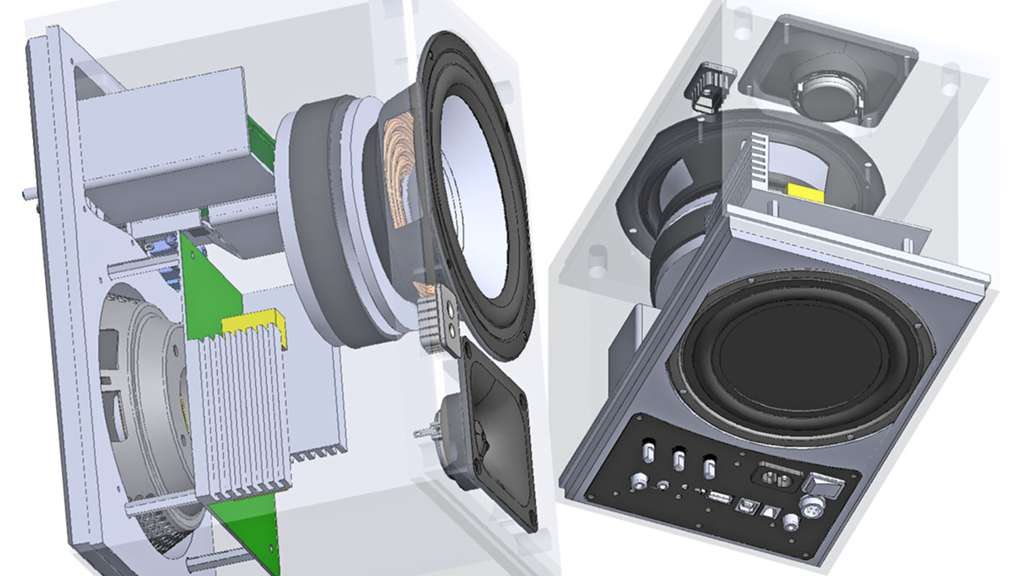

Now that we have our blueprint (the T/S parameters), let's understand the architectural principles of the structure we're building. A bass-reflex enclosure is more than just a box with a hole in it. That "hole," correctly termed a port or vent, is a precisely engineered element that turns the entire enclosure into a tuned acoustic system.

How It Works: The Helmholtz Resonator

The core principle behind a bass-reflex speaker is the Helmholtz resonator, a concept dating back to the 1850s. Imagine blowing across the top of a bottle to create a tone. The bottle's cavity (the air inside) and its neck form a resonator. In a speaker, the enclosure's internal volume is the "cavity," and the port is the "neck."

When the speaker cone moves backward into the enclosure, it pressurizes the air inside. In a sealed box, this trapped air acts like a spring, pushing back on the cone. In a bass-reflex box, this pressure escapes through the port. The air within the port has mass, and the air inside the box has springiness. Together, they form a resonant system. By carefully choosing the enclosure volume and the port's dimensions (length and diameter), we can "tune" this system to a specific frequency (Fb).

At and around this tuning frequency, the sound wave emerging from the port is in phase with the sound wave coming from the front of the speaker cone. The two waves reinforce each other, leading to a significant boost in output at that frequency range. As Audio Intensity explains, this resonance is the key to the enhanced bass response.

Key Advantages

When designed correctly, a bass-reflex system offers several compelling benefits over its sealed counterpart:

- Extended Low-Frequency Response: The primary goal. A ported box can achieve a lower cutoff frequency (f3, the point where bass output is down by 3 dB) than a sealed box of a similar size, effectively extending the frequency response.

- Increased Efficiency: Around the tuning frequency, the port's output adds to the driver';s, resulting in a sensitivity boost of up to 3 dB. This means you get more bass for the same amount of amplifier power, a significant advantage for lower-powered amplifiers often paired with full-range drivers.

- Reduced Cone Excursion: At the tuning frequency, the port is doing most of the work. The air in the port provides a high acoustic load on the driver, drastically reducing the cone's movement. This leads to lower distortion and increased power handling at those critical low frequencies.

Potential Downsides

The benefits of a bass-reflex design come with trade-offs that must be managed:

- Transient Response: The resonant nature of the system can sometimes lead to a slightly less ";tight" or ";articulate" bass compared to the crisp response of a well-designed sealed enclosure. This is often described as group delay, where bass notes can sound slightly smeared or "slower."

- Port Noise: If the port is too small for the amount of air being moved, turbulence can occur, creating an audible "chuffing"; or "whistling" sound, especially at high volumes. Proper port sizing is crucial to avoid this.

- Steeper Roll-off: Below the tuning frequency, the output from the port begins to move out of phase with the driver, causing cancellation. This results in a much faster drop-off in bass response, typically at 24 dB per octave, compared to the gentler 12 dB per octave slope of a sealed box.

The Core Task: A Step-by-Step Guide to Enclosure Design

This section is the heart of our project. Here, we translate theory into practice, using the driver's T/S parameters to calculate the three critical values for our enclosure: the internal volume (Vb), the tuning frequency (Fb), and the port dimensions. This process, once understood, is a repeatable method for any bass-reflex design.

Step 1: Choose Your "Alignment" - Defining the Sound Character

The first and most crucial decision is selecting an "alignment." In this context, an alignment is not a physical adjustment but a standardized design target. As audioXpress explains, Thiele's genius was recognizing that a speaker system's acoustic response is analogous to an electrical high-pass filter. By designing the box to match a known filter characteristic (like Butterworth or Bessel), its performance becomes predictable.

The choice of alignment dictates the trade-offs between bass extension (how low it goes), frequency response flatness (absence of peaks or dips), and transient response (how ";fast" and "tight" the bass sounds). The driver's Qts is the primary factor determining which alignments are achievable.

A Quick Check: Efficiency Bandwidth Product (EBP)

Before diving into alignments, a simple calculation called the Efficiency Bandwidth Product (EBP) can give a strong indication of whether your driver is a good candidate for a ported box. The formula is:

EBP = Fs / Qes

A widely accepted guideline, mentioned on sites like Audiophonics, is:

- EBP near 100 (or higher): The driver is generally well-suited for a bass-reflex enclosure.

- EBP near 50 (or lower): The driver is likely a better candidate for a sealed enclosure.

- Values in between: The driver may work well in either type of enclosure, making the choice dependent on design goals.

Common Alignments for DIY

There are many alignments, but a few are particularly popular and effective for DIY projects:

- Butterworth (B4): Often considered the standard for a ";maximally flat" response. It provides excellent bass extension with no peak in the frequency response, offering a very balanced sound. However, it is a "discrete" alignment, meaning it's only achievable with a driver that has a very specific Qts, typically around 0.38 to 0.40.

- Quasi-Butterworth (QB3/SBB4): This is a highly flexible and popular family of alignments. As detailed in an article by Audio Judgement, alignments like QB3 (Quasi-3rd-order Butterworth) and SBB4 (Sub-Boom-Box) work for a wider range of Qts values (often 0.2 to 0.4). They provide an excellent balance of good bass extension and reasonable box size, making them a go-to for many designers.

- Bessel (BE4): This alignment prioritizes transient response above all else. It yields the tightest, most articulate bass with minimal group delay. The trade-off is that it has less low-frequency extension compared to a Butterworth alignment. Like the B4, it is a discrete alignment requiring a specific Qts (around 0.33).

Step 2: Calculate Enclosure Volume (Vb) and Tuning Frequency (Fb)

Once you've chosen an alignment, the math is surprisingly straightforward. The calculations rely on two key ratios, `α` (alpha) and `H`, which are derived from complex filter theory but are readily available in published alignment tables or from speaker design software.

The core formulas are:

Vb = Vas / αFb = H * FsWhere:

Vbis the net internal volume of the enclosure.Fbis the Helmholtz resonance (tuning frequency) of the enclosure.VasandFsare the parameters from your driver's spec sheet.α(alpha) is the system compliance ratio.His the tuning ratio.

The process is simple: find a reliable source for alignment tables (like those in Vance Dickason's "Loudspeaker Design Cookbook" or provided by online calculators). Look up your chosen alignment (e.g., QB3) and find the row that corresponds to your driver's Qts. That row will give you the necessary `α` and `H` values to plug into the formulas. As audioXpress points out, these two normalized parameters are all you need to start defining the physical box.

Step 3: Calculate Port Dimensions

With the box volume (Vb) and tuning frequency (Fb) determined, the final step is to design a port that will achieve that tuning. This involves choosing a port area and then calculating the required length.

Port Area and Shape

The area of the port is critical. If it's too small, the air velocity inside can become excessive at high volumes, leading to compression (the port can't move enough air) and audible noise (chuffing). A common rule of thumb is to start with a port area that is between 1/3 and 1/2 of the driver's effective piston area (Sd). Ports can be round (often made from PVC pipe) or rectangular/slot-shaped (built from the same material as the enclosure). Both are acoustically effective, though round ports with flared ends are often preferred to minimize turbulence.

Port Length Formula

The length of the port is inversely proportional to the box volume and the square of the tuning frequency. There are many variations of the formula, but a standard one for a single, round port is:

Lv = ( (23562.5 * D^2) / (Fb^2 * Vb) ) - (0.732 * D)Where:

Lvis the length of the port in centimeters.Dis the inner diameter of the port in centimeters.Fbis the tuning frequency in Hz.Vbis the net box volume in liters.

Note: This formula includes an "end correction" factor (the `0.732 * D` part), which accounts for the fact that the air just outside the port openings also behaves as part of the moving mass.

Practical Trade-offs

You will quickly discover a fundamental trade-off in port design. For a given tuning, a larger diameter port (which is better acoustically) requires a much longer length. A smaller diameter port can be very short but is more prone to noise. Sometimes, the calculated port length is too long to physically fit inside the enclosure. In such cases, the designer must compromise: either accept a smaller, potentially noisier port, or reconsider the enclosure tuning or volume. This is a key challenge in designing small, low-tuned speakers, as explored in an example by audioXpress.

Putting It All Together: A Practical Design Example

Theory is essential, but a practical example makes the concepts concrete. Let's walk through the entire design process for a hypothetical—but realistic—full-range driver to see how these numbers translate into a real-world speaker design.

1. The Driver: "The Audiophile's Choice FC8"

Imagine we have purchased a promising 8-inch full-range driver. After consulting the manufacturer's specification sheet, we have the following key Thiele-Small parameters:

- Fs (Free Air Resonance): 45 Hz

- Qts (Total Q): 0.38

- Vas (Equivalent Compliance Volume): 28 Liters

- Qes (Electrical Q): 0.41

- Sd (Piston Area): 210 cm²

2. Choose the Alignment

Our first step is to determine the best enclosure type and alignment.

First, we run the EBP check:

EBP = Fs / Qes = 45 Hz / 0.41 ≈ 109.8

With an EBP well over 100, this driver is an excellent candidate for a bass-reflex enclosure.

Next, we select the alignment based on Qts:

The driver's Qts is 0.38. This is right in the sweet spot for a Butterworth (B4) alignment. We'll choose this target because it promises a maximally flat frequency response, which is a great goal for a high-fidelity system.

3. Calculate Box Volume and Tuning

Now we consult a B4 alignment table (or use a tool like WinISD). For a driver with a Qts of 0.38, the standard B4 alignment parameters are:

- α (alpha): ≈ 1.4

- H: ≈ 1.0

With these ratios, we can calculate our target volume and tuning frequency:

Enclosure Volume (Vb):

Vb = Vas / α = 28 Liters / 1.4 = 20 Liters

Tuning Frequency (Fb):

Fb = H * Fs = 1.0 * 45 Hz = 45 Hz

So, our design target is a 20-liter enclosure tuned to 45 Hz.

4. Calculate Port Dimensions

The final step is to design a port that will tune our 20-liter box to 45 Hz.

First, choose a port diameter. A good starting point is a port with an area of about 1/4 to 1/3 of Sd. Our Sd is 210 cm². Let's aim for an area around 50-70 cm². A 3-inch (7.62 cm) diameter port has an area of about 45 cm², which is a bit small. A 4-inch (10.16 cm) port has an area of 81 cm², which is better. Let's try a more common size in between: a 3-inch internal diameter (D = 7.62 cm) port.

Now, calculate the required length (Lv) using our formula:

Lv = ( (23562.5 * D²) / (Fb² * Vb) ) - (0.732 * D)

Lv = ( (23562.5 * 7.62²) / (45² * 20) ) - (0.732 * 7.62)

Lv = ( (23562.5 * 58.06) / (2025 * 20) ) - 5.58

Lv = (1368209.5 / 40500) - 5.58

Lv = 33.78 cm - 5.58 cm ≈ 28.2 cm

A length of 28.2 cm (about 11.1 inches) is quite long but should be manageable in a box with a 20-liter volume, especially if placed diagonally.

5. Final Design Summary

- Driver: The Audiophile's Choice FC8

- Enclosure Type: Bass-Reflex, Butterworth (B4) Alignment

- Internal Volume (Vb): 20 Liters (net, after accounting for driver and port displacement)

- Tuning Frequency (Fb): 45 Hz

- Port: One round port, 7.62 cm (3 inches) in diameter and 28.2 cm (11.1 inches) long.

Beyond the Numbers: Practical Tips for a Successful Build

The calculations provide a solid, scientific foundation for your speaker, but the final sonic result also depends on the quality of construction. Here are some practical tips to ensure your build is as successful as your design.

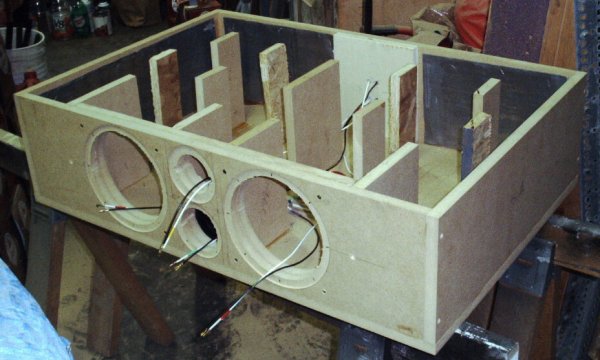

Enclosure Construction

- Material Choice: The ideal cabinet material is dense, rigid, and non-resonant. Medium-Density Fiberboard (MDF) is the most common choice for DIY builders due to its high density, uniform consistency, and affordability. High-quality Baltic Birch plywood is another excellent, albeit more expensive, option. Avoid particleboard or solid wood, as they can have voids or resonate undesirably.

- Bracing is Not Optional: This is one of the most overlooked aspects by beginners. Large, unbraced cabinet panels will vibrate in sympathy with the music, coloring the sound and smearing detail. As one experienced builder on a DIY Audio forum states, "Cabinet resonances are bad. Use braces." Connect opposing panels with wooden dowels or "window" braces to dramatically increase rigidity.

Acoustic Damping

Lining the internal walls of the enclosure with acoustic damping material serves a critical purpose: it absorbs high- and mid-frequency sound waves bouncing around inside the box. These internal reflections can otherwise escape through the driver cone or the port, interfering with the direct sound and reducing clarity. Common materials include:

- Acoustic Foam: Egg-crate or convoluted foam is effective and easy to apply.

- Poly-fil / Fiberfill: The same material used in pillows can be loosely stuffed into the enclosure.

- Denim Insulation or Wool: Natural fibers are excellent sound absorbers.

A good practice is to line the back, top, bottom, and side walls, but be careful to keep the area immediately around the port's internal opening clear to ensure unrestricted airflow. As noted by designer Troels Gravesen, heavy damping can slightly lower the effective tuning frequency of the port.

Software and Tools

While manual calculations are great for understanding the principles, software can save time and provide deeper insights. Many free and powerful tools are available to automate the design process:

- WinISD: A long-standing and popular freeware program for Windows. It allows you to input T/S parameters, model various alignments, and visualize the predicted frequency response, cone excursion, and port air velocity.

- Online Calculators: Websites like SubBox.pro and SpeakerBoxLite offer web-based tools that can quickly calculate box volumes and port dimensions, often providing cutting plans as well.

- Speakerbench: A more advanced, web-based application created by industry experts that provides highly accurate modeling for various low-frequency alignments.

Measure, Don't Guess

For the dedicated enthusiast seeking ultimate precision, it's important to know that manufacturer-provided T/S parameters can have a tolerance of +/- 10% or more. Furthermore, a driver's parameters can change slightly after a ";break-in" period. For this reason, professionals and serious hobbyists often measure the parameters of their specific drivers themselves using a tool like the Dayton Audio DATS (Dayton Audio Test System). While not essential for a first-time builder, measuring your own parameters is the definitive way to ensure your enclosure is perfectly optimized for your driver.

Conclusion: From Parameters to Performance

The journey from a raw speaker driver to a finished, high-performance audio system is a deeply rewarding one. We've seen how a handful of numbers—the Thiele-Small parameters—can serve as a reliable blueprint, guiding us through the complexities of acoustic design. By understanding the fundamental principles of the bass-reflex system and methodically applying proven alignment theories, we can move beyond guesswork and engineer an enclosure that is scientifically tailored to extract the very best performance from a full-range driver.

We've demystified the process: starting with the driver's "DNA" (Fs, Qts, Vas), choosing a sonic character through an alignment (like the flat response of a B4), and translating those targets into physical dimensions for the enclosure volume (Vb) and port. Our practical example demonstrated that with a few key formulas and a clear process, anyone can design a speaker with predictable and excellent results.

Ultimately, building your own speaker is a beautiful fusion of science and craft. The math provides the solid foundation, ensuring the acoustic principles are sound. The craftsmanship in construction—the rigid, well-braced cabinet and careful assembly—brings that design to life. The satisfaction of listening to a speaker you not only built but also designed, one that produces a coherent, detailed, and surprisingly deep soundstage, is an experience unmatched in the world of audio.

So, gather your tools, select your driver, and start your project. Experiment with different drivers and alignments. Embrace the process of learning and creation. The world of DIY audio is waiting, and the satisfaction of building a speaker that sounds truly exceptional is your reward.